Max. Feeding Size: 0.03-1mm

Capacity:1-200tph

Processing Materials: iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin ore and colombite ore, etc.

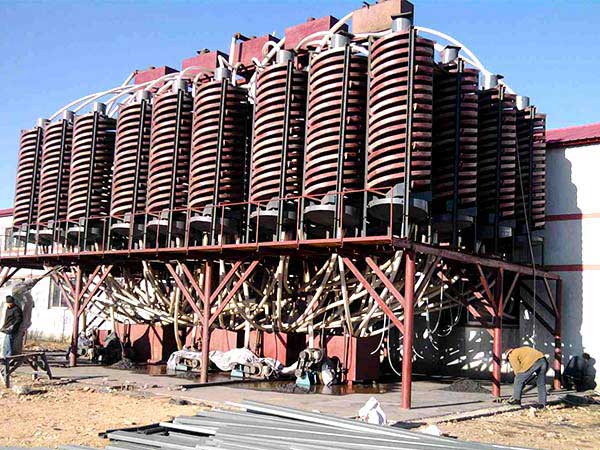

Spiral chute, also called spiral separator, integrates the advantages of spiral concentrator, shaker and centrifugal separator together. Spiral chute separator is the best machine, used for ore mining and ore separating, especially for ore mining in beach, riverside and coast. Spiral chute separator is suitable for separating ores with size from 0.02mm to 0.3mm like iron ore, ilmenite, chromite, pyrite, zircon, rutile, monazite, tungsten ore, tin ore and colombite ore, etc.

1. Light weight, dust and rust-proof, anti-corrosion, no noise

2. Strong adaption to changes of feeding amount, ore concentration and ore grade

3. Stable work, easy control, high enrichment, high recycling rate

4. Small floor space, water and power consumption

5. Simple structure, high working capacity, easy installation

6. Small investment, fast capital return

At first, we stand up the gravity spiral chute separator, calibrate the perpendicular line and fasten it at place with brandreth or wood. Then, the ore sands are delivered into two feeding mouths via pump and added with water for adjusting concentration. The ore pulp naturally flows down and an inertia force is produced. Under the forces of inertia and gravity, ores are separated from sands. Finally, concentrates flow into the hopper through pipe. The sand tailings flow into another hopper via pipe, then are discharged out by pump.

| Model | Processing capacity (t/h) |

| DL2000 | 15-40 |

| DL1500 | 8-16 |

| LL1200 | 4-6 |

| LL900 | 2-3 |

If you have any problems or questions about our products or need our support and assistance, please feel free to write us, we will reply to you within 24 hours, and never reveal your information to the third party. Thank you!