Max. Feeding Size: 5.5-75 (kw)

Capacity:1-200tph

Processing Materials: wood charcoal, gypsum, coal, ore, iron oxide, iron powder and aluminum ash.

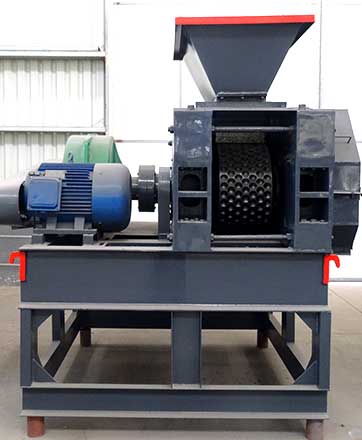

General Introduction:

Charcoal briquette machine is also known as charcoal briquetting making machine, charcoal ball press machine, or charcoal pressure ball machine. It processes bamboo, wood, shell, straw (except for rice and wheat straw) and other granular (length ≤ 5mm, diameter ≤ 3mm) waste whose moisture content is less than12% through high temperature, high pressure process, extruded into rod solid with center hole without any binder.

Applied Materials and Applied Fields

Charcoal briquette machine is mainly used for making bamboo charcoal powder, toner, toner, toner, coke hookah carbon, graphite, carbon shell, jujube wood, blue carbon carbon powder, activated carbon powder, powder, waste of materials. It can produce square, ball-egg-shaped, round, egg-shaped, regular round, column, line, bar, bread type, pillow type and other special shapes. And also charcoal briquette machine is widely used in refractories, power plants, metallurgy, chemical industry, energy, transport, heating, barbecue, animal husbandry, industry, agriculture and other fields. This machine is suitable for single assignments and the proliferation of briquette production line, but also can conduct the liquidity operations.

1. Reasonable design, guaranteed quality, simple structure, easy operation, compact structure, small footprint, labor-saving, and power-saving.

2. The design of the automatic control of electric heating devices can be randomly adjust material humidity to ensure stable discharge and improve work efficiency.

3. The product main parts adopt wear resistant material with a special treatment, so it can make continuous suppression production, and durable.

4. Suitable for all kinds of biomass raw materials and less energy consumption, high production efficiency.

| Model | Roller Diameter (mm) |

Capacity(t/h) | Power(kw) | Reducer |

| FTMQ290 | 290 | 1-2.5 | 5.5-7.5 | 350 |

| FTMQ360 | 360 | 3-5 | 7.5-11 | 350 |

| Heavy FTMQ360 | 360 | 3-5 | 7.5-11 | 400 |

| FTMQ430 | 430 | 5-8 | 15 | 400 |

| Heavy FTMQ430 | 430 | 5-8 | 15 | 500 |

| FTMQ500 | 500 | 8-11 | 30 | 650 |

| FTMQ650 | 650 | 10-15 | 37-45 | 750 |

| FTMQ750 | 750 | 20-25 | 45 | 750 |

| FTMQ850 | 850 | 20-28 | 55 | 850 |

| FTMQ1000 | 1000 | 25-35 | 90 | 1000 |

If you have any problems or questions about our products or need our support and assistance, please feel free to write us, we will reply to you within 24 hours, and never reveal your information to the third party. Thank you!